In the fast-evolving world of protective coatings, Polyurethane Machinery Corporation (PMC) has established itself as a leading provider of equipment for polyurea and spray foam applications. As a division of PMC Global, Inc., the company is known for delivering durable, reliable machinery that meets the needs of both residential and commercial sectors.

With a strong focus on quality and innovation, PMC offers a wide range of products, including the popular PHX Series proportioners, designed to handle demanding applications. Whether it’s for insulation or advanced coatings, PMC’s equipment is trusted across various industries.

In this article, we’ll take a closer look at PMC’s history, its commitment to excellence, and the features that make their machines stand out. Let’s explore what sets PMC apart in this competitive market.

What Is PMC Polyurea Business?

PMC Polyurea Business specializes in providing high-quality equipment for applying polyurea coatings and spray foam insulation. Their machinery is trusted by contractors for both small residential projects and large commercial jobs, offering reliability and excellent performance every time.

Headquartered in Lakewood, New Jersey, PMC is well-positioned to serve clients worldwide, benefiting from strong logistics connections. This central location helps the company maintain its commitment to American-made quality while expanding its global reach. With a focus on durability and innovation, PMC continues to lead the industry in providing top-tier machinery for protective coatings and insulation.

Read Also: Premium Business Travel Services – Make your Trip Effortless!

The Evolution Of Polyurea Technology – The Latest Innovations Now!

Polyurea technology has evolved significantly since its discovery in the 1980s. Initially, it was mainly used for waterproofing in industrial settings. However, as time passed, improvements in its formulation and application techniques have opened the door for polyurea to be used across a wide range of industries.

PMC has played a major role in advancing this technology by developing specialized equipment that makes the application process faster, more efficient, and reliable. Thanks to their focus on creating user-friendly machinery that addresses the unique needs of contractors, PMC has helped make polyurea a go-to material for protective coatings and insulation. As a result, polyurea has become an essential part of many industries today.

Why Choose PMC Polyurea Machinery?

When it comes to polyurea and spray foam insulation equipment, PMC stands out for its performance, durability, and commitment to innovation. Here’s why many contractors and businesses turn to PMC for their machinery needs:

Built For Durability And Tough Conditions:

PMC machinery is designed to perform in even the most challenging environments. Whether you’re working in extreme heat or cold, their equipment is built to last and withstand harsh conditions. This ensures consistent performance and reduces downtime, even on demanding projects.

Ease Of Use And Minimal Maintenance:

PMC’s equipment is known for its simplicity, making it easy for contractors to use, even without extensive training. The intuitive controls and user-friendly interface allow for smooth operation, while the durable design minimizes the need for frequent repairs. This means less maintenance and more time spent on projects.

Precision And Consistency:

PMC machines deliver consistent and precise results with every use. The electro-mechanical systems offer more accuracy than traditional circuit-board-based systems, ensuring a stable, high-quality application. This level of precision helps contractors achieve flawless coatings and insulation every time.

Read More: Www.Hura-Watch.Net Business Archives – Revolutionizing Business Data!

Cost-Effective And Long-Term Investment:

While PMC equipment may have a higher upfront cost, its durability and low maintenance make it a smart investment in the long run. With fewer repairs and longer-lasting performance, you get more value over time. This makes PMC machinery a cost-effective choice for businesses looking to maximize their return on investment.

Comprehensive Customer Support:

PMC is committed to providing exceptional customer service, offering training and support to ensure clients can get the most out of their equipment. Their team is available for troubleshooting, technical advice, and guidance whenever needed. This dedication to customer support helps contractors work confidently with PMC machines.

Key Products In PMC’s Polyurea Line – Top Equipment For Your Projects!

PMC offers a variety of products designed to meet the needs of contractors working with polyurea. Here’s a quick look at some of their top equipment:

- PHX Series Proportioners: The PHX Series includes models for different project sizes, offering reliable mixing and spraying. These proportioners ensure precision and efficiency for both small and large jobs.

- Spray Foam Insulation Machines: PMC also offers spray foam insulation machines, built with the same durability and ease of use as their polyurea machines. These are perfect for insulation in both residential and commercial buildings.

- Polyurea Pumps and Heaters: PMC’s pumps and heaters ensure smooth application and consistent curing of polyurea. This combination reduces downtime and improves overall efficiency.

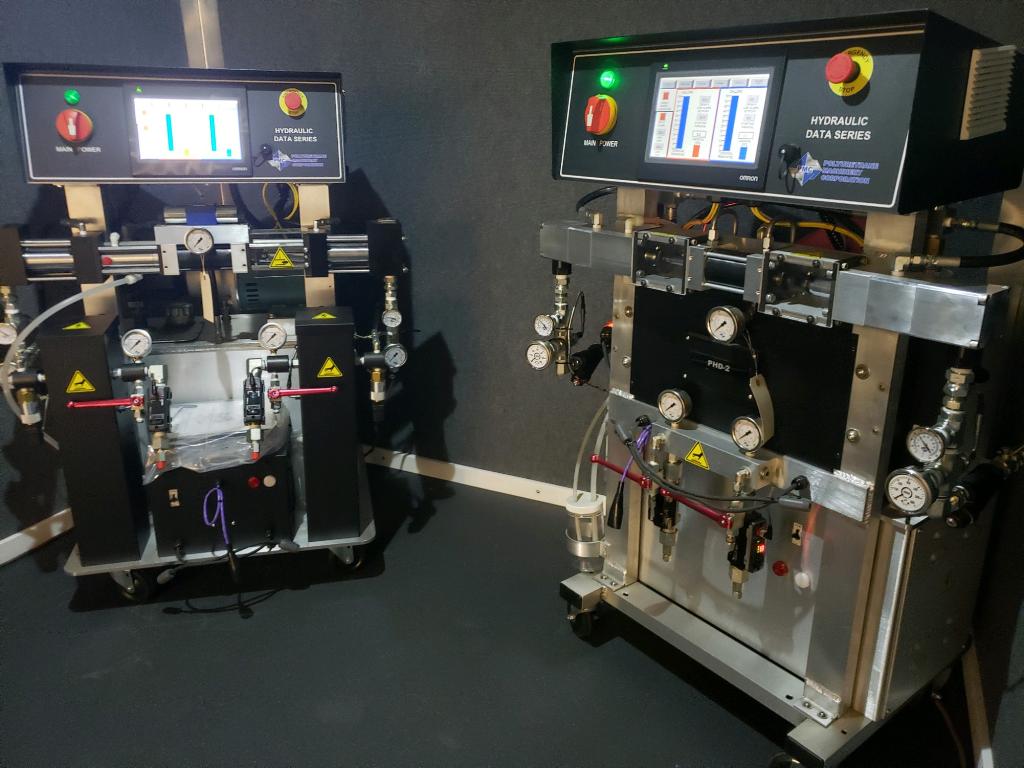

- Hydraulic Proportioners: For larger-scale projects, hydraulic proportioners offer extra power and precision. These machines are ideal for industrial applications that require high output.

- Mobile Spray Systems: PMC’s mobile spray systems provide portability and convenience, making them perfect for contractors working on multiple sites. They allow for quick setup and efficient spraying on the go.

What Is The PHX Series? – Need To Know!

The PHX Series is a line of proportioners designed and manufactured by PMC for applying polyurea and spray foam coatings. These machines are known for their reliability, ease of use, and versatility across a range of project sizes.

| Model | Output | Ideal For | Key Features |

| PHX-2 | 1.7 GPM | Small residential & light commercial projects | Compact, portable, easy to use |

| PHX-25 | 2.0 GPM | Medium-scale residential & commercial jobs | Balanced power, reliable performance |

| PHX-40 | 2.5 GPM | Medium to large commercial & industrial jobs | Efficient, cost-effective for larger projects |

| PHX-55 | 3.25 GPM | High-demand, large-scale commercial & industrial projects | High output, designed for heavy-duty applications |

As you can see, the PHX Series offers a range of options suited for different types of projects. Whether you need a compact machine for smaller jobs or a powerful one for large commercial applications, PMC’s PHX Series ensures reliable performance and high-quality results.

Read More: Grow Google Business Profile Audience – Proven Tips For Instant Growth!

Innovative Features Of PMC Polyurea Machines – See What Sets Them Apart!

PMC’s polyurea machines are designed with several key features that improve performance, reduce downtime, and enhance usability. Let’s explore these features in more detail:

- Electro-Mechanical Systems: PMC machines use durable electro-mechanical systems instead of fragile circuit boards, making repairs easier and more affordable. This results in fewer malfunctions and less downtime.

- Dual Heaters for Temperature Control: The dual-heater system ensures polyurea components are kept at the optimal temperature for consistent mixing and application. This helps reduce waste and improves the overall quality of the spray.

- Easy-to-Use Interface: PMC designs its machines with a user-friendly interface, making them simple to operate even for those with little experience. Contractors can quickly learn to use the equipment, saving time and effort.

- Compact and Portable Design: PMC machines are designed to be compact and portable, making them easy to transport between job sites. This feature is perfect for contractors working on multiple locations, ensuring flexibility and efficiency.

- Built-In Diagnostics: PMC’s built-in diagnostic system allows contractors to quickly identify and troubleshoot issues. This feature reduces downtime and helps keep projects running smoothly without costly delays.

Applications Of PMC Polyurea Machines – Perfect For Any Job!

Protective Coatings For Industrial Applications

One of the most common uses for PMC polyurea machines is applying protective coatings in industrial settings. Whether it’s for tanks, pipes, or concrete surfaces, polyurea provides a durable, waterproof, and chemical-resistant layer. PMC machines ensure a smooth, consistent application, protecting structures from wear and tear.

Commercial And Residential Insulation

PMC’s spray foam insulation machines are perfect for both commercial and residential insulation projects. These machines apply high-quality foam insulation to walls, roofs, and floors, helping to improve energy efficiency and reduce heating or cooling costs. Contractors can trust PMC equipment for consistent, reliable results every time.

Waterproofing For Construction Projects

Polyurea is also widely used for waterproofing construction projects, especially foundations, roofs, and parking decks. PMC machines help apply these coatings quickly and efficiently, creating a strong barrier against water intrusion, which is crucial for maintaining the longevity of buildings.

Bridge And Roadway Protection

PMC’s polyurea machines are used to protect bridges, highways, and roadways from environmental wear. The polyurea coatings help resist corrosion from chemicals, salt, and weather, extending the life of infrastructure and reducing maintenance costs.

Mining And Oil & Gas Industry

In mining and oil & gas industries, PMC’s equipment is used for coating and protecting equipment and structures exposed to extreme conditions. Polyurea is applied to protect against chemical exposure, corrosion, and wear, ensuring the longevity of equipment and safety of operations.

Read More: Cursed-Memes.Com Business – How Dark Memes Became A Big Success!

How To Start A PMC Polyurea Business? – Your Guide to Success!

Starting a PMC polyurea business is a rewarding venture with the right approach. Here are the essential steps to guide you:

- Research the Market: It’s important to understand the demand for polyurea in your local area before getting started. By researching industries such as construction, infrastructure, and insulation, you can identify potential clients.

- Invest in the Right Equipment: To provide high-quality services, you’ll need to purchase reliable PMC polyurea equipment. Focus on machines that best suit the scale and type of projects you plan to take on.

- Obtain Proper Training: Training is key to using PMC equipment effectively and safely. Make sure to take advantage of training resources to master the machinery and ensure your work meets industry standards.

- Build a Strong Network: Networking with local contractors, distributors, and suppliers will help you grow your business. Establishing these relationships can lead to new projects and valuable referrals over time.

- Market Your Services: Once you have everything in place, focus on advertising your services through both online and offline channels. A website, social media, and local ads can help raise awareness of your new polyurea business.

- Focus on Customer Satisfaction: Providing outstanding customer service ensures clients will return for future projects and recommend your business. Satisfied customers are more likely to spread the word and help your business grow.

PMC Customer Support And After-Sales Services – Reliable Support For Every Need!

PMC is committed to providing exceptional customer support long after the sale. They offer training and technical assistance to ensure contractors get the most out of their equipment. Additionally, PMC provides responsive after-sales services to help with any issues that may arise, keeping projects running smoothly.

Their team is always ready to offer repairs, maintenance, and troubleshooting, ensuring minimal downtime. Overall, PMC’s focus on customer care helps build long-term relationships with clients, making them a trusted partner in the polyurea industry.

Contact PMC Polyurea – Get In Touch For Expert Support!

If you have any questions or need assistance with PMC’s products, feel free to reach out through the following channels:

| Contact Information | Details |

| Phone | (732) 415-4400 |

| Fax | (732) 364-4025 |

| Polyurethane Machinery Corporation | |

| @equipmentpmc | |

| Polyurethane Machinery Corporation on LinkedIn | |

| YouTube | PMC Equipment Channel |

| @PMC_Equipment |

Feel free to connect with us on social media for updates, tips, and more!

The Future Of PMC Polyurea Business – What’s Next For Innovation?

The future of PMC polyurea business looks promising, with increasing demand for durable, eco-friendly coatings across various industries. As construction and infrastructure projects grow, the need for polyurea coatings in applications like waterproofing, insulation, and corrosion protection will continue to rise.

Furthermore, with ongoing advancements in technology, PMC is likely to introduce even more efficient and user-friendly equipment. This means contractors will have access to better tools that improve performance and reduce costs. Ultimately, as the market for polyurea grows, PMC’s focus on innovation and quality will help them maintain a strong position in the industry.

FAQs:

Can PMC equipment be used in harsh weather conditions?

Yes, PMC machines are built to withstand extreme temperatures, from freezing cold to intense heat. Whether you’re working in the Arctic or the desert, PMC equipment ensures smooth operation. This makes them a versatile choice for global contractors.

How long do PMC machines last?

PMC equipment is known for its durability and longevity. Designed with high-quality materials and minimal electronic components, it ensures longer service life. With proper maintenance, these machines can perform reliably for many years.

What maintenance is required for PMC polyurea machines?

PMC machines require minimal maintenance, primarily cleaning and routine checks. Their electro-mechanical design reduces the need for frequent repairs. Regular servicing helps to keep the machines running at peak performance.

Do PMC machines require specialized training to operate?

While PMC machines are user-friendly, specialized training ensures you get the best performance. The company offers comprehensive training sessions for contractors. With this training, operators can efficiently use and maintain the equipment.

What makes PMC’s polyurea equipment different from competitors?

PMC machines are designed with simplicity and durability in mind, avoiding fragile circuit boards. Their electro-mechanical systems also reduce the risk of failures. This unique design feature sets PMC apart, providing a more reliable and cost-effective solution.

Conclusion:

PMC’s polyurea business offers reliable, high-quality equipment designed to meet the needs of contractors across various industries. With a focus on durability, ease of use, and excellent customer support, PMC has built a strong reputation in the market.

As demand for polyurea applications continues to grow, PMC is well-positioned for the future. Ultimately, their commitment to innovation and customer satisfaction makes them a trusted partner for any polyurea project.

Read More: